Welcome to T.S.E. Trading

Your trusted supplier of high-quality stainless steel products and solutions.

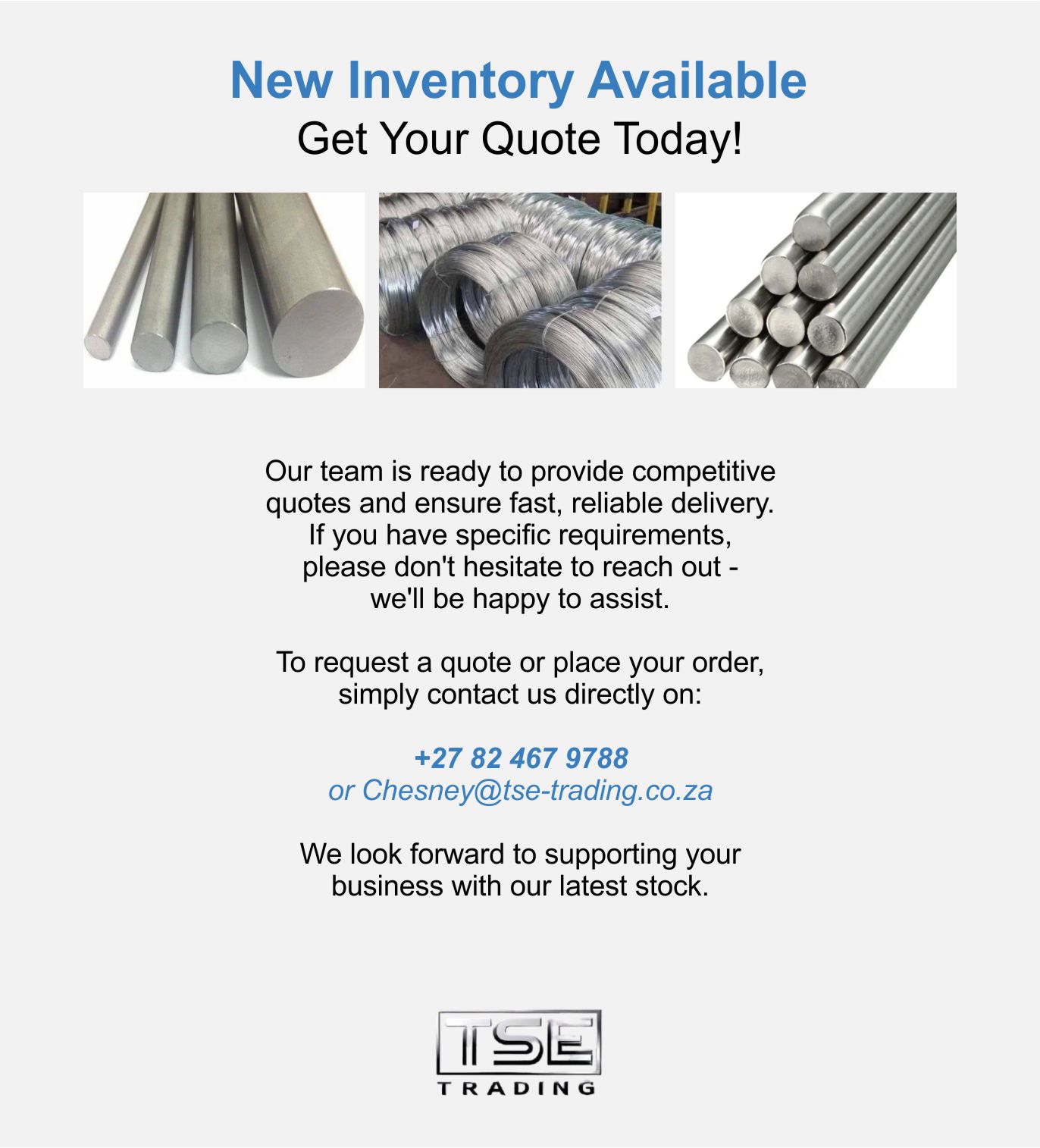

Our Products

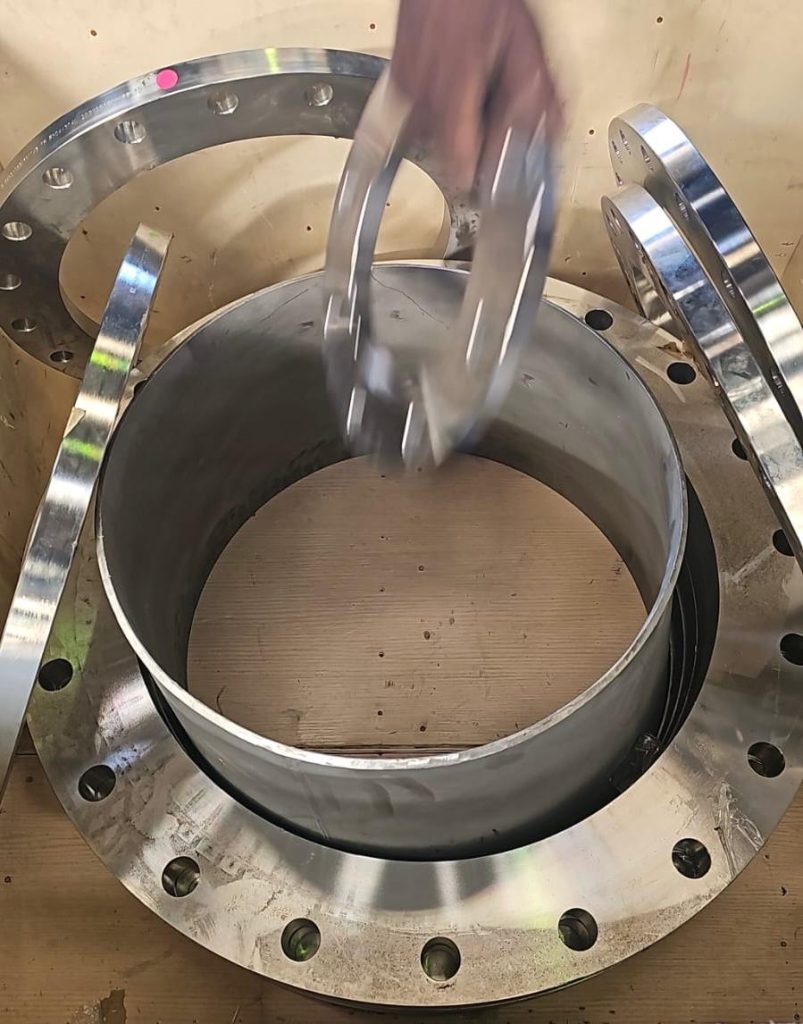

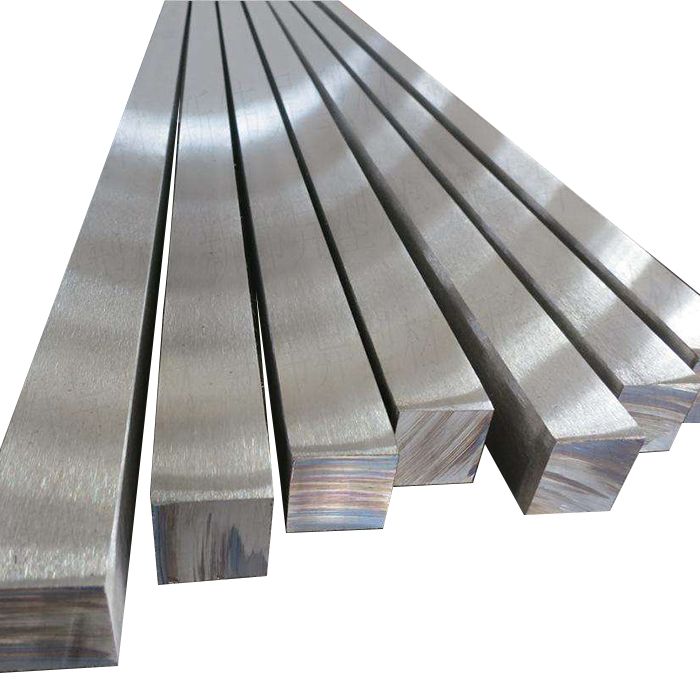

At T.S.E. Trading, we provide a comprehensive range of stainless steel products for various industries. We specialize in:

Based on its operational and marketing statements, TSE Trading’s core purpose is to serve as a trusted partner and supplier of premium stainless steel materials and solutions. The company operates on a foundation of open communication and mutual trust, prioritizing the development of strong, long-term relationships over transactional interactions. This relationship-centric approach is a cornerstone of its business model. The company’s target market is diverse, catering to various industries which require high-quality stainless steel materials for their projects.

A notable aspect of its business is its service to “walk-in customers,” indicating that its client base extends beyond large-scale B2B projects to include smaller-scale, immediate needs from individual customers.

TSE Trading offers a specialized yet comprehensive product portfolio of stainless steel materials. The company supplies materials in multiple stainless steel grades, each selected for its specific properties and suitability for different applications.

TSE Trading provides several value-added services that demonstrate its commitment to tailored solutions. These unique offerings position TSE Trading as a supplier capable of meeting specific, project-based requirements.

The primary operational strengths of TSE Trading are rooted in its customer-centric and agile business model. The company emphasizes a highly “personalized service,” working closely with its clients to fully understand their unique requirements and provide tailored solutions. This commitment to close collaboration and relationship-building is a key differentiator in the market.

A significant operational advantage is the “hands-on management” approach, where the director and shareholder are directly involved in daily operations. This active leadership ensures consistent service quality and allows for a more personalized touch. This direct involvement facilitates faster decision-making and a deeper understanding of customer needs, which in turn enhances overall service quality.

TSE Trading’s focus is on “fast and reliable deliveries” and “prompt service” for both regular and walk-in customers. This responsiveness and inventory flexibility enable the company to fulfil orders efficiently, a critical factor for maintaining customer satisfaction and meeting project deadlines.

STAINLESS STEEL SPRING WIRE

Stainless steel spring wire is a high-strength, corrosion-resistant alloy wire used for manufacturing springs and wire forms.

• It is widely used in automotive, construction, mining, and industrial sectors across South Africa.

• Imported from global suppliers.

Stainless steel spring wire is a cold-drawn wire made from stainless steel grades that provide elasticity, fatigue resistance, and corrosion protection.

The main differences between spring wire grades lie in their chemical composition, mechanical strength, and corrosion resistance

• Pickling and Annealing – Removes scale and improves ductility.

• Cold Drawing – Reduces diameter and increases strength.

• Heat Treatment – Adjusts hardness and elasticity.

• Surface Finishing – Polished, bright, or coated finishes for corrosion protection.

“Your Size, Our Precision.”

“Cut to Your Exact Specifications - Every Time.”

Our Services

We are committed to providing solutions that go beyond just supplying products. Our service offering includes:

Personalized Service: We work closely with customers to understand their unique needs and provide tailored solutions.

Stockholding & Custom Orders: A comprehensive product range and the ability to stock specific items tailored to your needs.

Fast & Reliable Deliveries: On-time deliveries, every time. We offer regular shipments and prompt service for walk-in customers.

Competitive Pricing: Quality stainless steel at prices that meet your budget.

After-Sales Support: Our commitment to excellence doesn’t end with delivery. We ensure that all your future needs are anticipated and met with continued support.

A LIFETIME OF DEDICATION

Tanya Papadopoulos

The greatest strength of the South African stainless steel sector is undoubtedly its people, who believe in the material’s ability to enhance and sustain the South African economy no matter how onerous the challenges it faces. For this reason, our profile series focuses on stainless professionals who embody the entrepreneurial spirit and who will shape our industry for years to come. In this issue, we speak to Wire Products Stainless Steel Director Tanya Papadopoulos.

Building Strong Connections

At T.S.E. Trading, we focus on more than just transactions—we build relationships.

Commitment to Quality: We prioritize delivering only the best stainless steel materials, ensuring your projects are built on solid foundations.

Transparency & Trust: Open communication and mutual trust are the cornerstones of our partnerships.

Hands-On Management: Our directors and shareholders are actively involved in the day-to-day operations, ensuring a personalized touch and consistent service.

We are dedicated to meeting and exceeding your expectations through every step of our collaboration. Our goal is to ensure that your business benefits from reliable service, quality products, and a true partnership built on trust.

Whether you’re in construction, manufacturing, or any other industry, we have the right materials to meet your needs.

Contact

Have questions or need a quote?

Phone: +27 (0) 11 824-7600

Email: tanya@tse-trading.co.za

Address: 152 Haring Road, Wadeville, Germiston

Business Registration Number: 1996/012262/07